-

>CONVEYOR BELT CLEANER

-

>IMPACT BED

-

>SKIRT RUBBER BOARD

-

>CONVEYOR PULLEY LAGGING

-

>CONVEYOR PULLEY

-

>CONVEYOR BELT

-

>UHMWPE IDLER ROLLER

-

>PLASTIC HDPE SHEET

-

>OTHERS

Address: 0716,Building E,No.13 Longsheng Str.,Comprehensive reform zone,Taiyuan,Shanxi,China

Tel: (+86)0351-8206817

Cell: (+86)18734141882(wechat)

Fax: (+86)0351-7196098

Mail: bumtresd@bumtresd.com

Website: www.bumtresd.com

Post: 030032

The pulley is an important part of the conveyor, which is generally divided into two types: the drive pulley (Figure 1) and the bend pulley (Figure 2).

Our drive pulley is divided into steel smooth pulley and rubber lagging drive pulley.

The steel smooth pulley is generally used on the small volume and no slope conveyor, but requires lower environment humidity, while the surface of the rubber lagging drive pulley has large friction coefficient, which can provide a greater driving force and increase the service life of the pulley and belt, suitable for the conveyor used under high humidity environment , long distance and large volume. Now the rubber lagging drive pulley is widely applied in drive pulley.

The rubber lagging drive pulley can be divided into hot casting rubber and cold wrapping rubber according to the procedure (Figure 3).

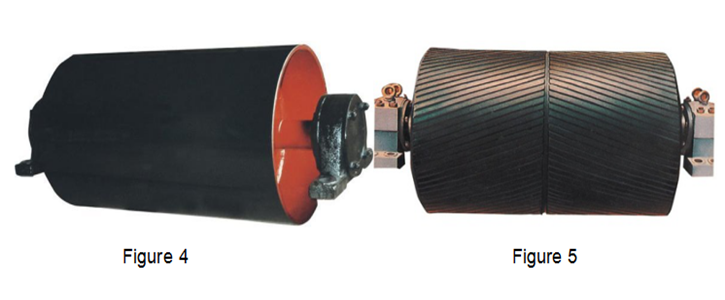

The rubber lagging drive pulley is divided into smooth casting rubber pulley (Figure 4), herringbone groove rubber pulley, diamond groove rubber pulley, polyurethane hot casting rubber pulley and ceramic lagging pulley .

The herringbone groove rubber pulley (Figure 5) is a rubber layer with herringbone groove added to the steel smooth surface of the drum, which can greatly increase the friction coefficient between the belt and the drum. When under humid environment, the groove can cut off the water film, make water no logged, at the same time when the conveyor belt and the roller contacted, the surface of the conveyor belt can be squeezed into the groove. Due to the above two reasons, even working under the humid place, the friction coefficient will be very small. But this kind of pulley’s movement direction is herringbone, no reverse operation allowed.

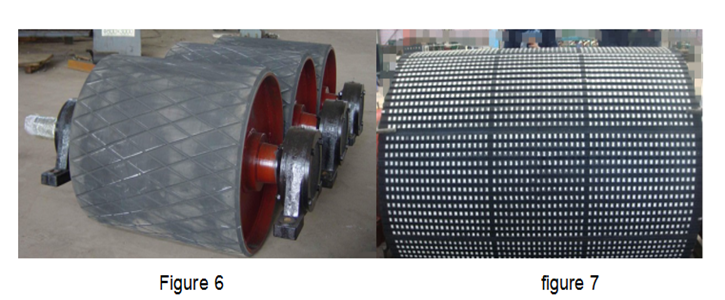

The diamond groove rubber pulley (Figure 6) is a rubber drum with diamond pattern. Compared with the herringbone groove rubber pulley, the diamond groove rubber pulley can run in two-way directions with excellent drainage performance.

The ceramic lagging pulley (Figure 7) is a new type of lagging. Hundreds of independent small ceramic bumps will be casted into a durable rubber board for each ceramic board surface, each ceramic bump has the characteristics of convex, under the general conveyor belt pressure, thousands of unique casting bump points can produce positive traction, prevent the belt from skidding, extend the service life of the conveyor pulley. At the same time, the underlying rubber has the flexibility to play a good impact resistance. Each ceramic rubber board has a certain distance groove, can discharge the foreign matter (dust, soil) on the drum along the groove , so that the drum has a unique self-cleaning function, especially suitable for humid working environment.

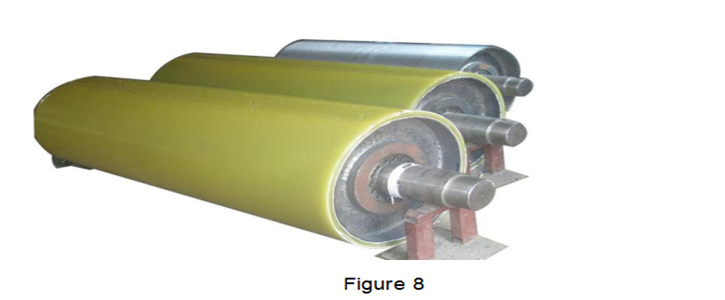

The polyurethane pulley (Figure 8) is coated with a layer of polyurethane adhesive on the metal drums. The polyurethane layer effectively improve the operation status of the conveying system, protect the metal drums from wearing, increase the resistance, and prevent the conveyor belt from slipping. The abrasion resistance of the polyurethane pulleys is significantly better than that of other pulleys.